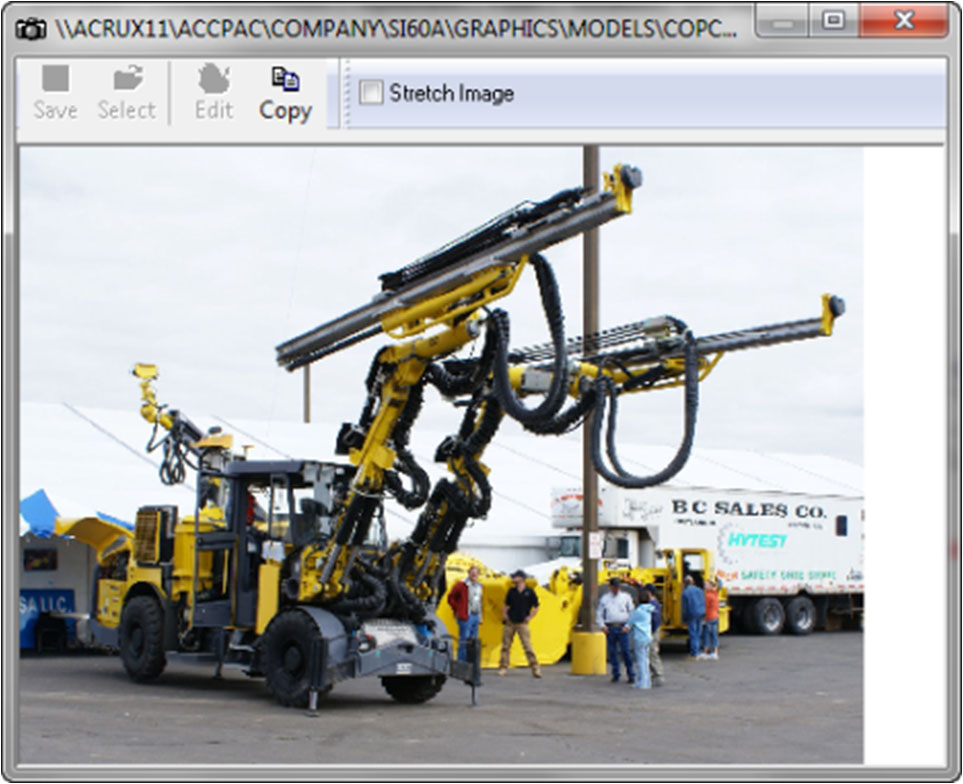

Manufacturing Equipment

- Models

- Meters

- Preventative Maintenance

- Faults

- Agreements

- Jobs

- Rentals / loan equipment

- Returns (RA/MRA)

- Refurbishments

- Management information

- Models

Manufacturer

Inventory mapping

Custom fields

Maintenance tracking

Meter tracking

Components

Accessories

Document storage

Fault history

Model parts list

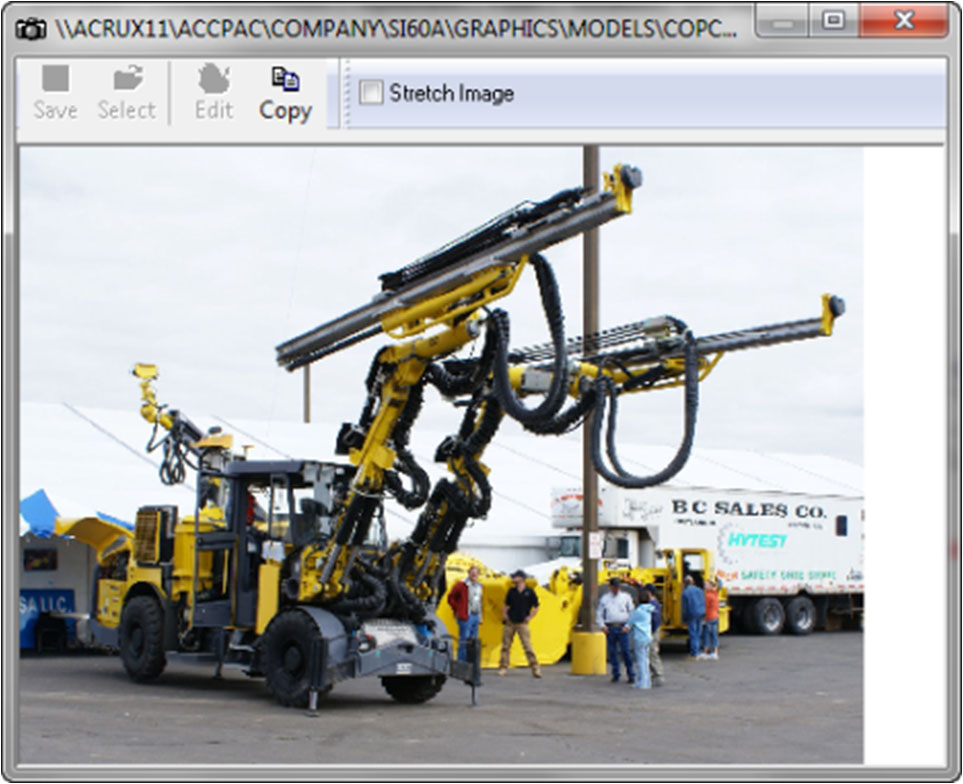

- Equipment

Inherits model basics

Serial number

Lot number

Install date

Last/next service date

Logged date

Warranty

Meters

Maintenance

Custom fields

Components

Life cycle history

GL segment override

Document storage

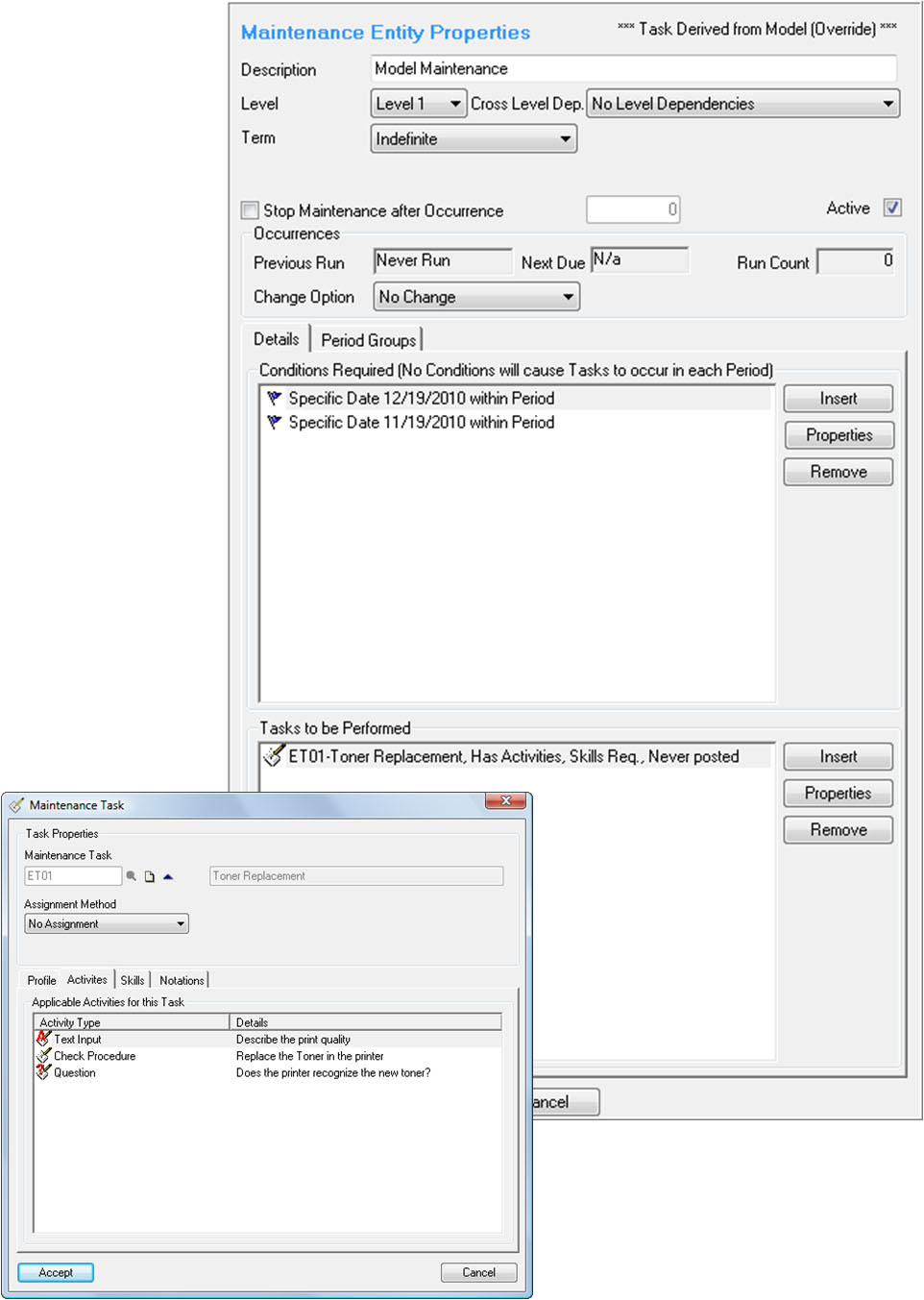

Advanced Maintenance

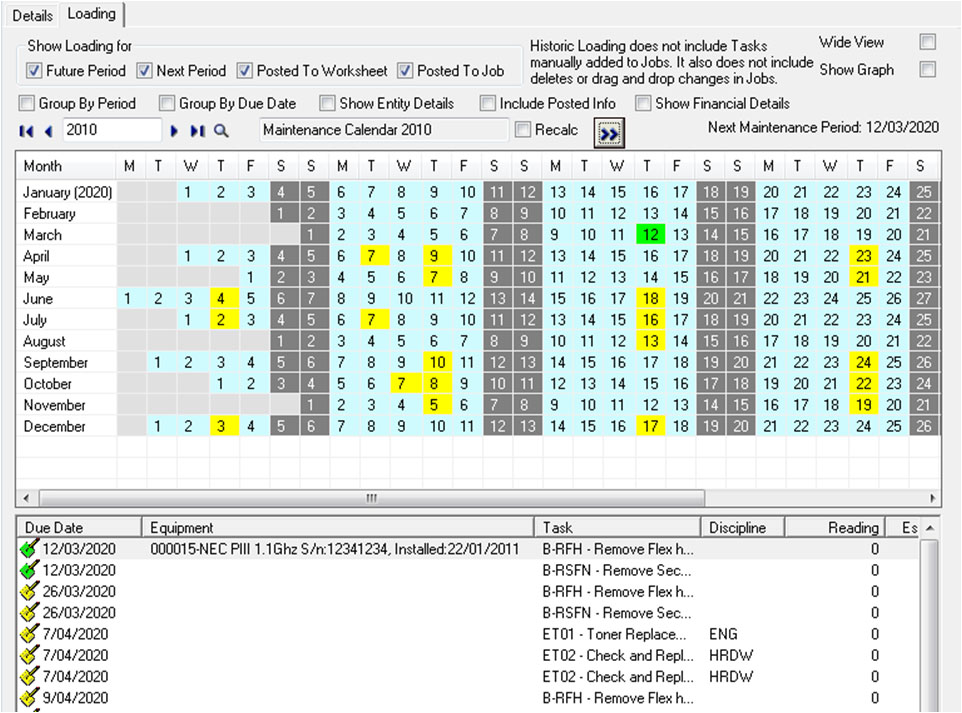

- Maintenance Schedule

Up to 15 levels

Cross level dependency

One off processing

Mandatory or optional

Create job or invoice

Automated activation

Use templates

Instructions on jobs

Pre allocate resources

Change options to set

next or previous run date

- 3 steps

Create a Plan

Specify Condition/s

Specify Task/s to perform.

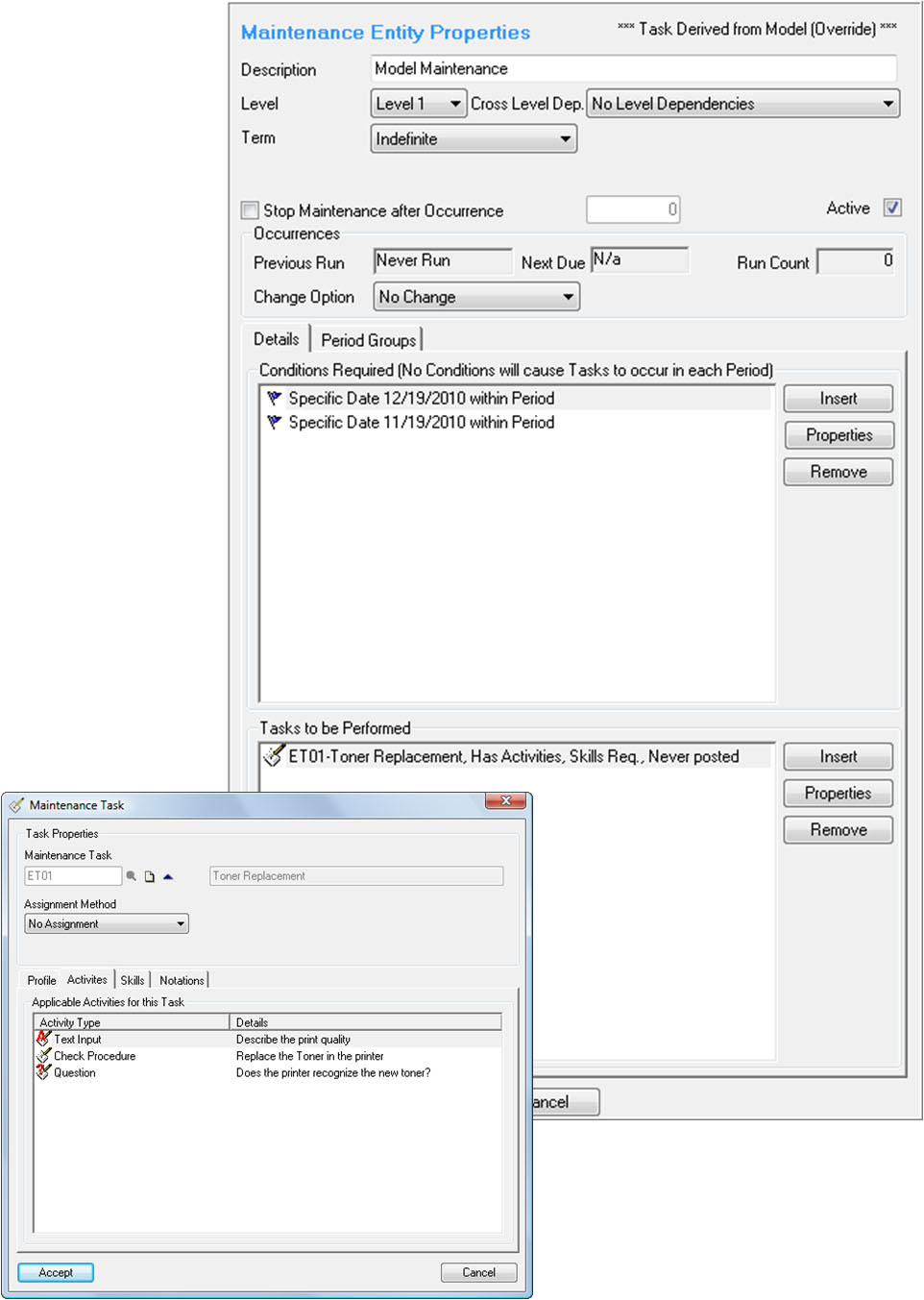

Advanced Maintenance

- Maintenance Types

Site/Equipment maintenance

Model maintenance (Publish to equipment)

- Conditions/Triggers

Frequency or schedule based

(daily/wkly/mthly/yrly…)

Meter or date based

Interval based

Site/Equipment conditional

Predictive maintenance

- Task & Activities

Check procedures

Numeric measurements

Text input

Questions

Multi choice list

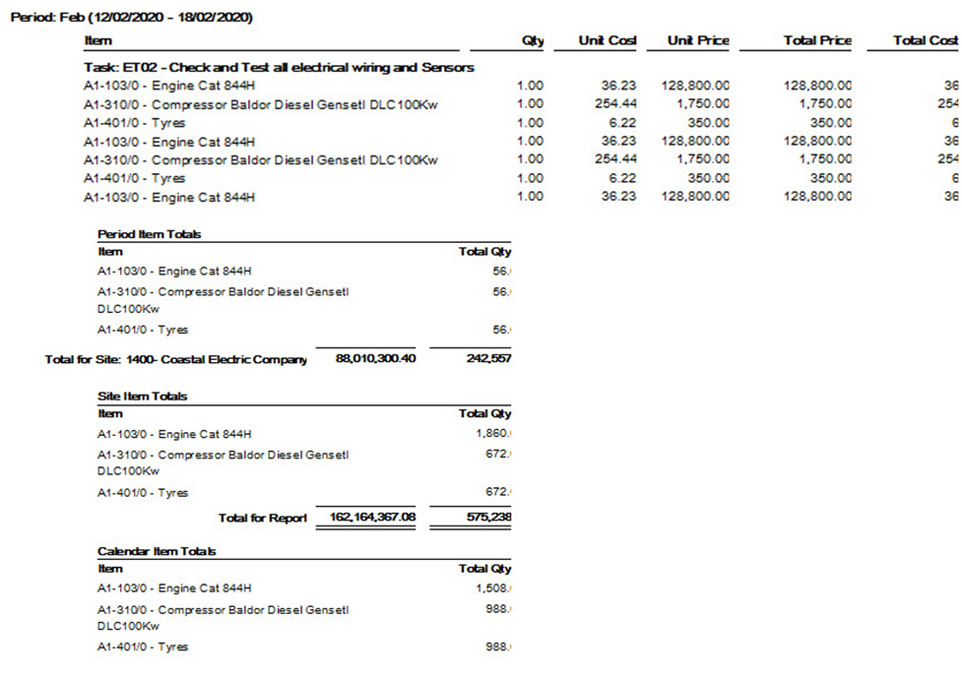

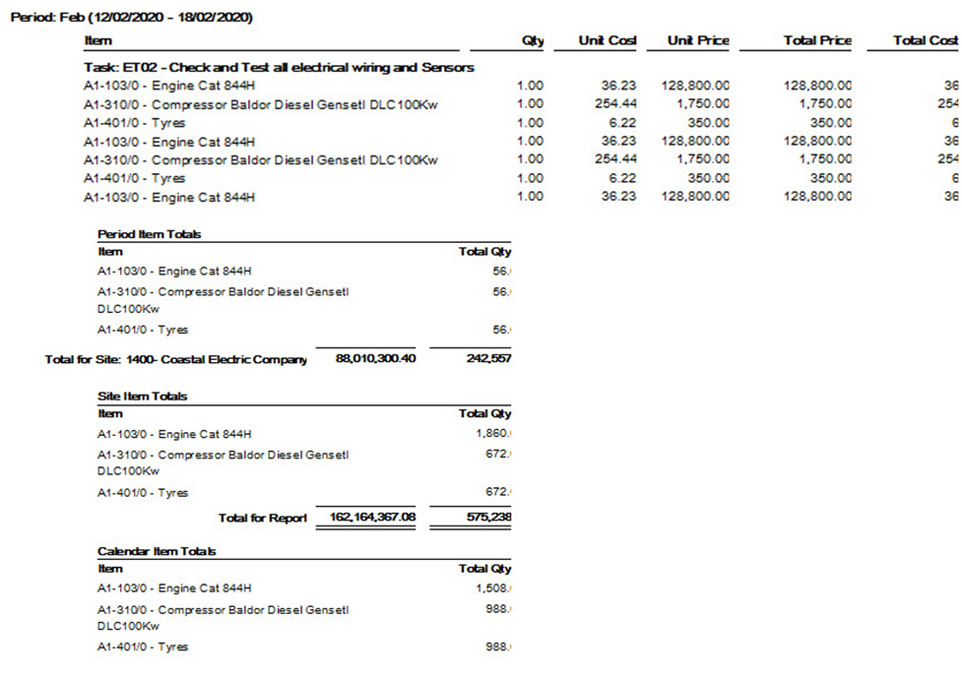

Advanced Maintenance

- Determine Inventory Requirement lists by period or date range.

- Order parts in advance so they are available for scheduled jobs.

- Obtain volume pricing discounts.

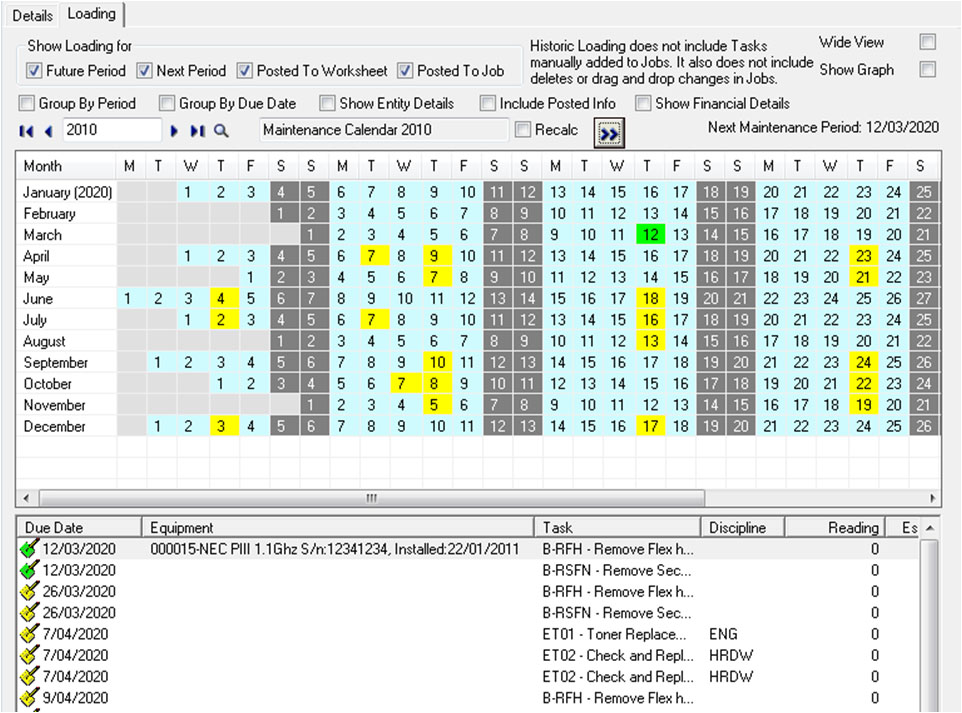

Advanced Maintenance

- Advanced Maintenance Process

SetupEnter meter readings if required

Post Calendar to Worksheets

Post worksheets to jobsComplete tasks and activities in jobs

View statistics

View profit , totals for period or year

Maintenance Cycling allows a repeat of a cycle at a particular point.

Maintenance conditions can be based on task completion date

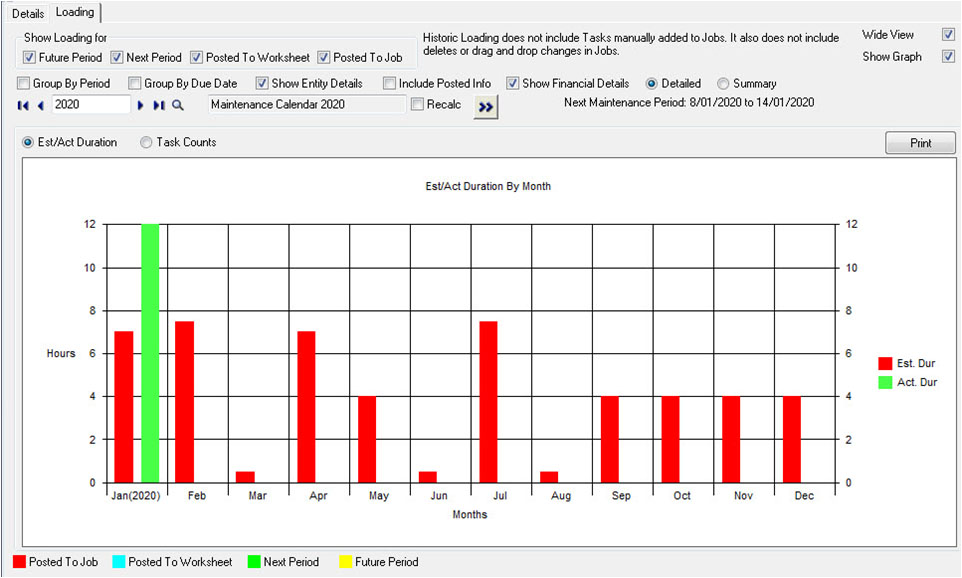

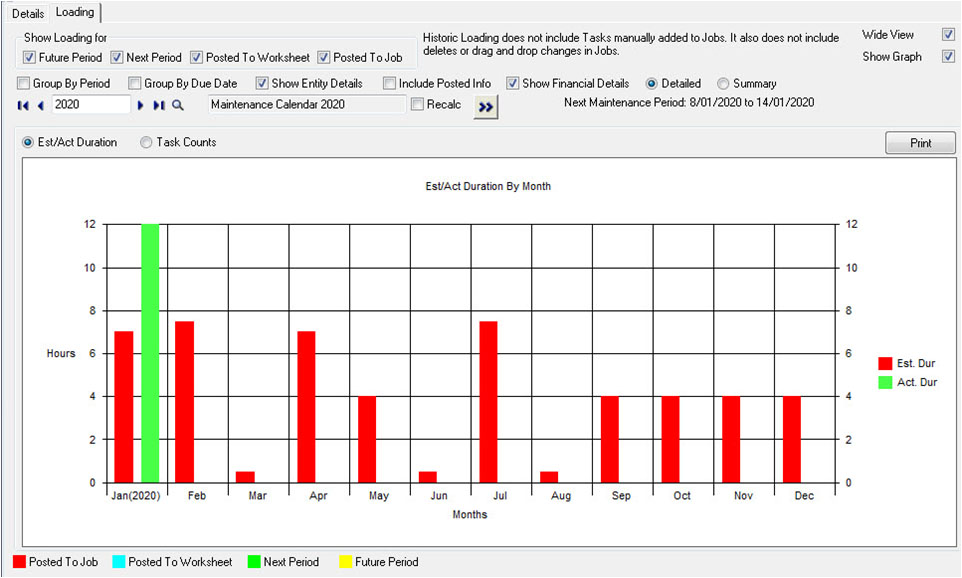

Advanced Maintenance

- Graph Task Duration per period.

- Compare estimated hours to actual.

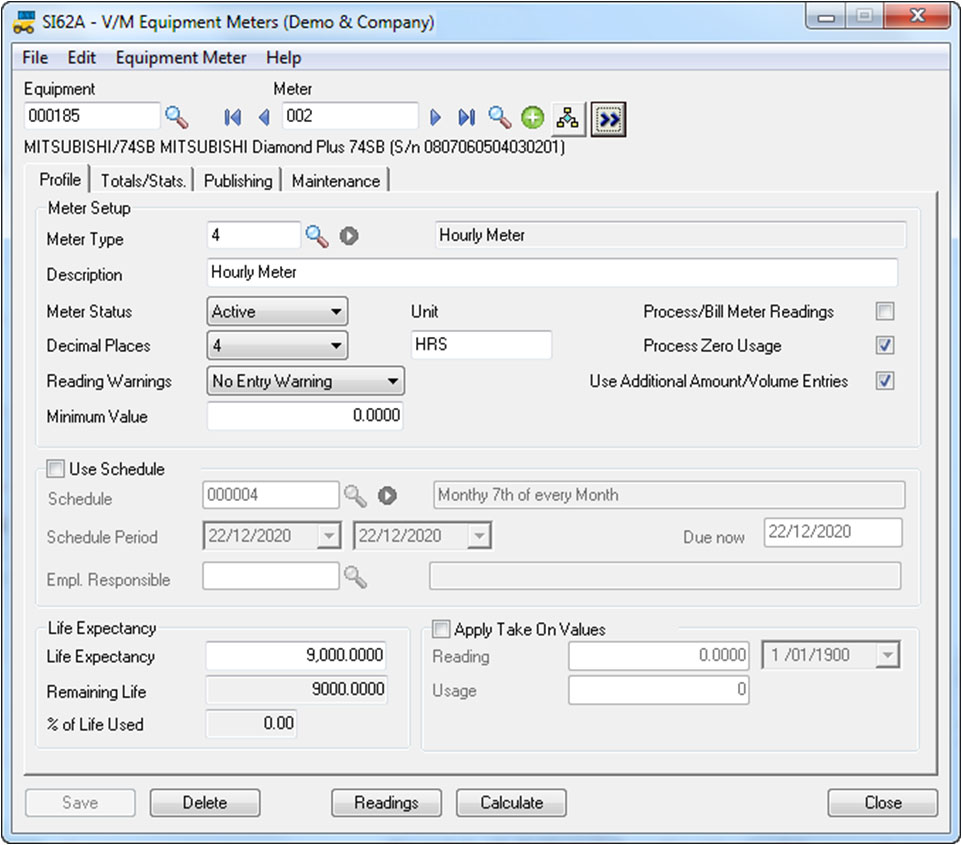

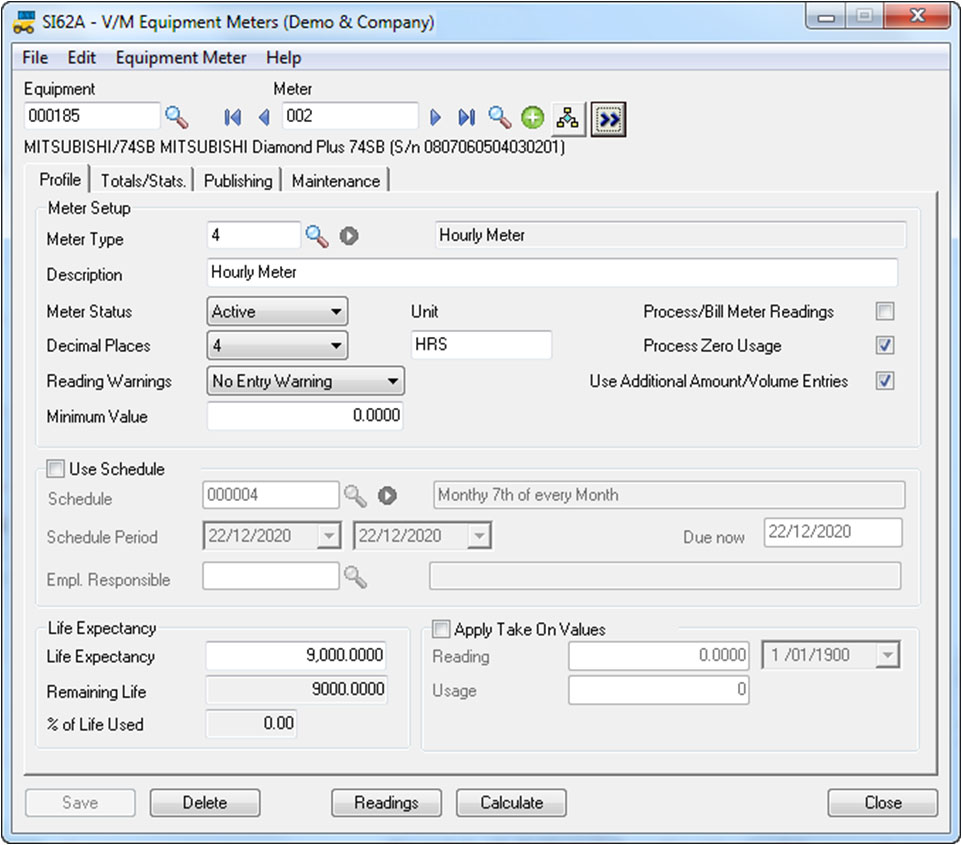

- Meters

Multiple meters per equipment

User defined quantity type

Last and current readings

Usage reading

Linked to planned maintenance

Reading schedules automated

Full history of meters

Apply take on values

Propagate Master Readings to

Components

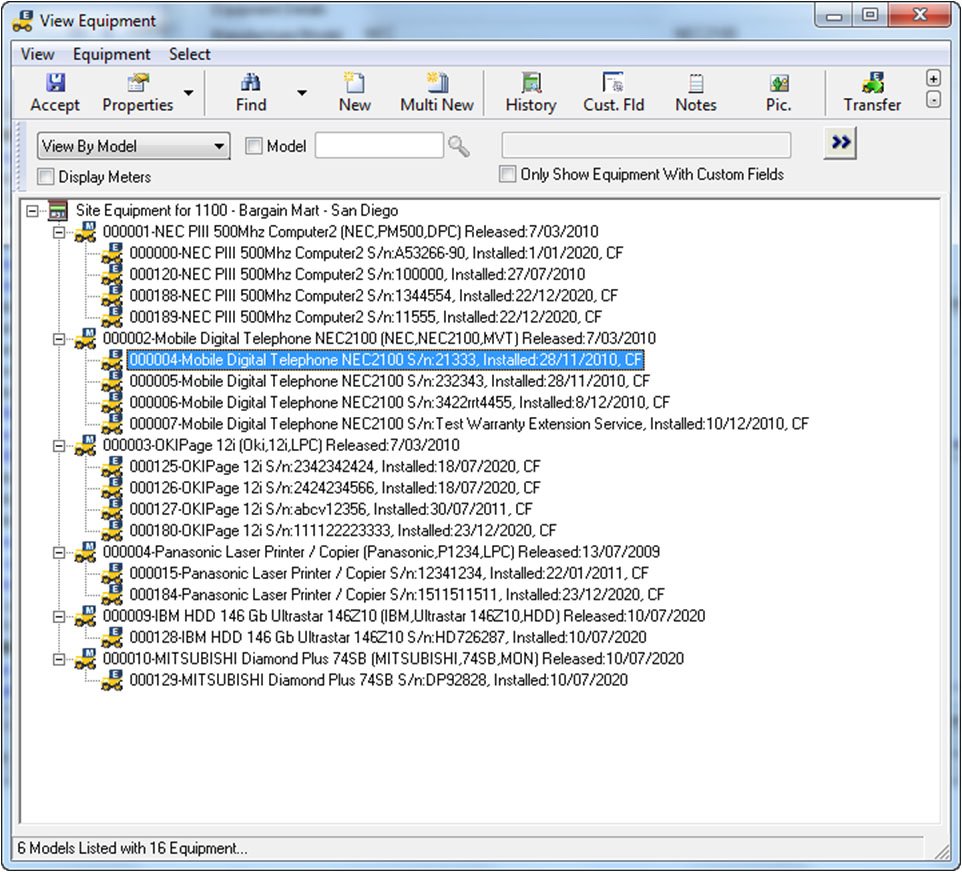

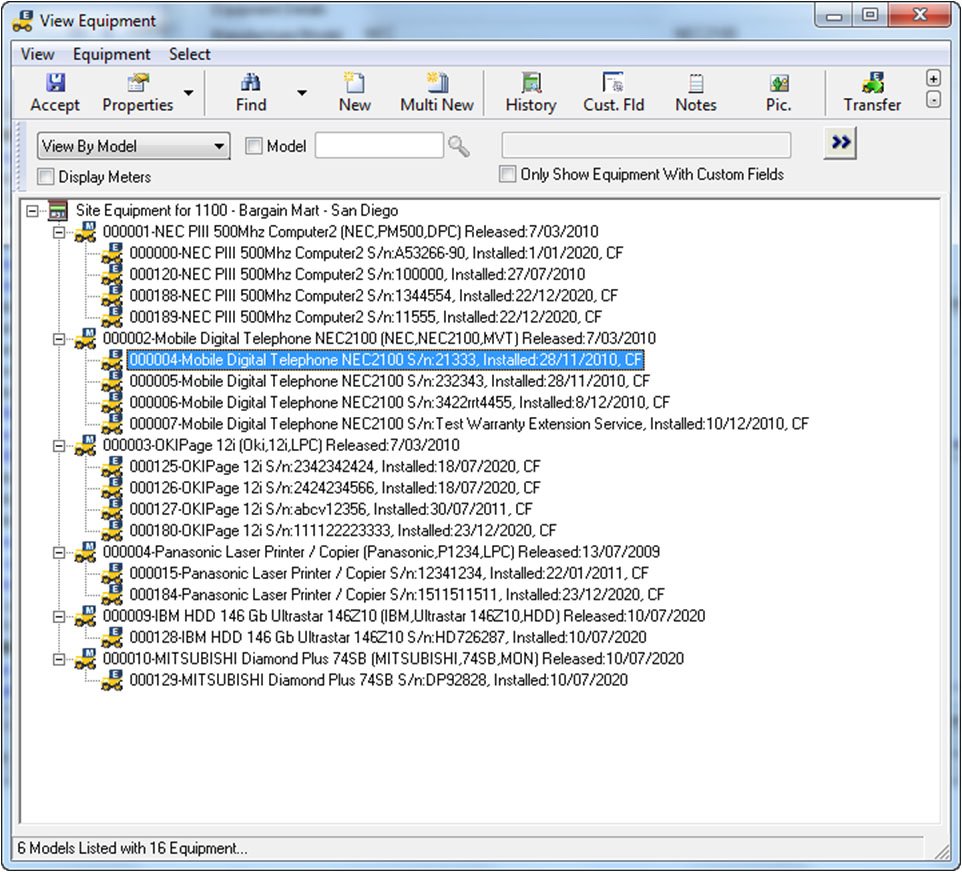

- Equipment Folio

List all equipment at a site by

Model

Site location

Equipment ID

Agreement

- Transfer Equipment

- Add new equipment

- Search

- History

- Life cycle costs/revenue

- Replacement / Refurbishment

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.OkPrivacy policy